It is no secret that I LOOOOOOOOVE silicone loaf molds. I especially love a tall and skinny silicone loaf mold.

Before we begin, I wanted to share two things!

Benjamin has finished his latest book (affiliate link), The Handy Little Sales Book for Scaredy Pants: 50 Quick Tips, Deep Thoughts and Practical Steps to Selling When You’re Scared.

We’re also having our annual eClass sale! All eClasses are half off until September 12!

There was a discussion in Saponification Nation about unmolding soap from silicone loaf molds, especially the tall and skinny mold. It can be a pain!

So here are some tips!

Force gel phase.

Gelled soap sets up harder and is easier to unmold. This is especially helpful if you have the corners breaking off during removal from the mold. This is usually soft ungelled soap that is breaking off. Use a heating pad or oven process to force your soap through gel phase until your soap is completely gelled is helpful.

Clay!

A random tip is to use clay to color your soap that you will be molding in a tall-skinny mold. Clay makes a harder soap by absorbing water. I’ve noticed that soap colored using clay unmolds very easily from silicone.

Discount your water.

Soaping with a water discount can help your soap to setup hard enough to unmold without any issues. I typically use 2 times my lye for water and never have issues unmolding. For example, if my soap recipe calls for 5 ounces of lye, I’ll use 10 ounces of water. You can even discount more than this if you are using a slow-moving recipe.

Linoleic & linolenic acids are sticky.

Soaps that are high in linoleic and linolenic acid oils are usually stickier. I found this out while making soap in Tibet using a locally processed sunflower oil and also again in Fiji using the same. The was not only sticky, but it sweat more as well. So if you’re using non high-oleic sunflower or safflower, hemp seed oil, canola oil or grapeseed oil your soap might be sticky.

Replace these with oils high in oleic acid, but not high in linoleic/linolenic acid, such as more olive oil, rice bran oils, avocado oil, or high-oleic sunflower or safflower.

Use sodium lactate.

You can try adding sodium lactate to your soap. Sodium lactate helps to create a harder soap upon unmolding. Add 1 teaspoon per pound (or 450 grams) of oils to your warm lye solution.

Same with salt.

Add 1 teaspoon of fine sea salt per pound (or 450 grams) of oils to your hot lye solution to dissolve.

Give it more time.

You might need to leave your soap in the mold an extra day or two. If you try unmolding after 24 hours and it doesn’t want to come out, try again after another 24 hours.

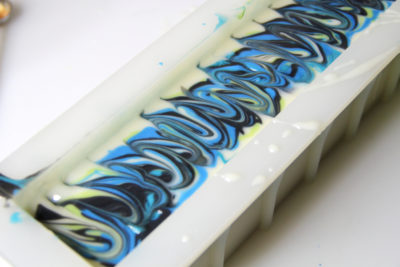

The tall & skinny soap mold is one of my favorite molds to use! Here are some soaps using the 12″ tall and skinny soap mold from Bramble Berry. All of these recipes/soaps unmolded after 24 hours. 🙂

How to Make Tallow Soap – Layered, Pencil Line Design with Natural Soap Colorants

Do you have any tips for unmolding from silicone? Simply post in the comments!

Happy Soaping!

-Amanda

Hi Amanda. I am from India. I am new to soaping. I hv do e two times cold process soap. First time I realised it had too much of water so I didn’t realise and forced the soap out. I used cucumber with45%water. Second I did with 33% water. Even though it harder a bit, it still refuses to come out of the mould. I use 50% hard oils.. Where did it go wro g.i use silicone mould

I use a large 6 lb silicone loaf and sometimes the soap doesn’t want to come out. If this happens, I will sometimes pop it in the freezer for a bit (maybe an hour?) and it comes out a lot easier. I haven’t had any bad results from this yet.

Hi Amanda…… I am from India……regarding unmolding from silicone molds….I find after 24 hour period…put the soap in the fridge for another few hours and they come out very easily.